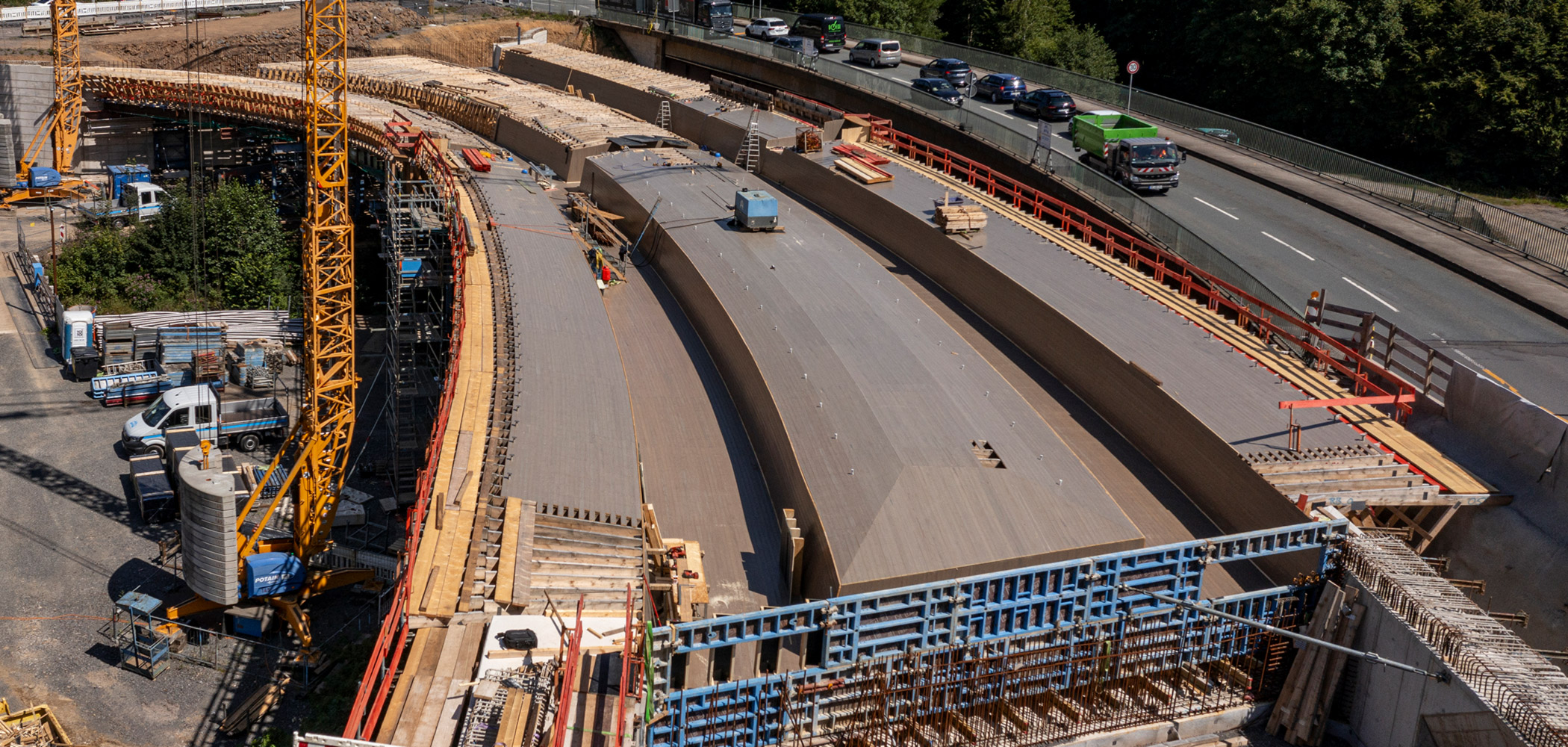

Concrete bridge formwork

With us you can build bridges and more!

Conventional wood is limited when it comes to the shuttering of exposed concrete structures. The substances in concrete and wood lead to a reaction that gives the concrete an undesirable rough, sandy surface. The method used until now for whitewashing on site is very complex and expensive.

The developers at Holzwerke Ladenburger have found an ideal solution for this: the formwork UltraUV elegantly gets round the described reaction by coating the wood used at the factory. The boards are also given a double-wedge groove. This makes them much easier to assemble.

Because UltraUV formwork can be re-used multiple times, the costs are paid off. The amount of time required for the replacement of the concrete formwork on the building site is also reduced. This allows projects to advance more quickly and the overall costs to be reduced. Sustainability is also taken into account once more by the multi-use characteristic.